Product details

Gruenberg Oven Company designs and manufactures a complete line of standard and custom Class A truck-in ovens to accommodate a variety of thermal thermal processing applications up to 1200°F. Our industrial Class A truck-in ovens are ideally suited for the following applications:

For applications handling volatile substances, our Class A truck-in ovens are designed to meet strict industry safety standards. With additional options, these truck-in ovens with solvent venting can also be used for applications such as paint baking, plastic curing, varnish baking, sterilizing, and rubber and epoxy curing.

Gruenberg Oven Company designs and manufactures a complete line of standard and custom Class A truck-in ovens to accommodate a variety of thermal thermal processing applications up to 1200°F. Our industrial Class A truck-in ovens are ideally suited for the following applications:

For applications handling volatile substances, our Class A truck-in ovens are designed to meet strict industry safety standards. With additional options, these truck-in ovens with solvent venting can also be used for applications such as paint baking, plastic curing, varnish baking, sterilizing, and rubber and epoxy curing.

- Easy to install and ship

- Lower cost than one piece ovens

- Wide range of options and controllers

- Electric or gas-fired

- Moisture-proof, non-combustible, non-settling, and asbestos-free insulation

- Energy-efficient, Incoloy sheathed, seamless tubular heaters

- Efficient horizontal airflow

- Standard and custom models

- Non-sparking air-movers

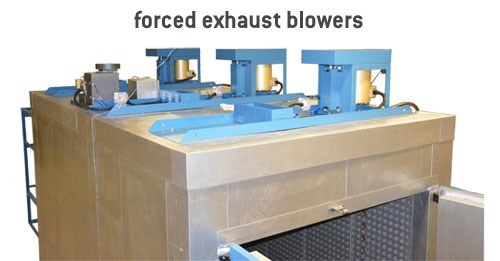

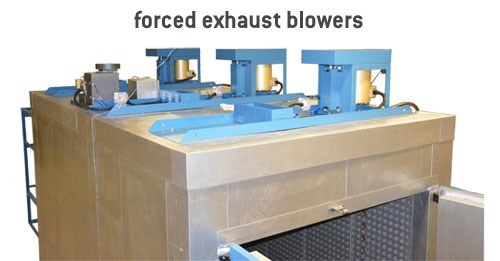

- Forced exhaust blowers

- Explosive Venting

- Standard non-sparking pressure relief latches on front doors

- Optional rear of the unit venting with safety cage

- Emergency stop push button

- Door switch

- Solvent monitor - optional

- Sterling performance of thermal processing applications up to 500°F

- Ideal for most solvent evaporation processes

- Additional options extend the range of applications

- Top quality construction is energy-efficient and minimizes equipment effort

- Heating elements designed to prevent radiant influence on the work in process

Superior Performance with Panelized Aluminum Construction Exterior

- Efficient 6" Insulation

- Pliable, final seal silicone rubber gaskets on ovens up to 650°F

- Less energy to maintain temperature

- Air-conditioning equipment doesn’t work as hard

- Pre-tested, ready for operation

- Motor and blowers to circulate air for uniform atmosphere

- V.F.D motor for circulation adjustment (CFM)

- Heater elements are Inconel sheathed