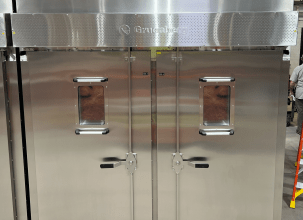

Industrial Oven & Sterilizer Manufacturer

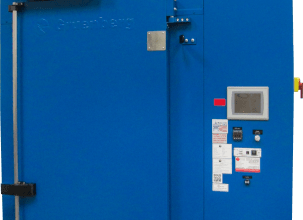

Gruenberg is a leading industrial oven manufacturer. Gruenberg's standard and custom industrial drying ovens, pharmaceutical dryers, and sterilizers are used for a variety of applications including curing, drying, annealing, dry heat sterilization, and other heat processing applications. Gruenberg industrial ovens and dry heat sterilizers are designed with high quality materials and available in both batch and conveyor configurations with maximum temperature ratings up to 1,200° F.

Gruenberg is a recognized global leader in the design, manufacturing, and after-market support for industrial ovens and sterilizers. Our expert engineers work alongside your team to create a custom solution to fit your application and your workspace. With every Gruenberg oven, you can count on durability, innovation, and superior performance.

Our aftermarket service team provides a comprehensive list of services for your Gruenberg industrial oven, dryer or sterilizer. All aftermarket services are performed by our factory trained technicians. Available Gruenberg oven aftermarket services include start-up and training, equipment installation options, preventative maintenance, temperature uniformity, GAMP documentation, relocation services, and more.