Product details

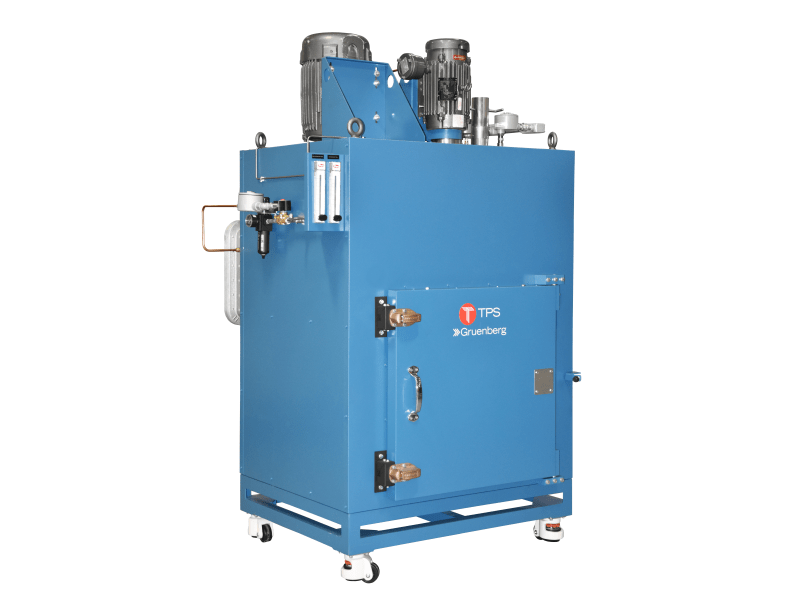

The Gruenberg Cyclone Series® is an industrial safety oven that utilizes a pair of non-sparking blowers to provide a patented ignition-free heating method. One blower circulates the airflow in the oven while a second blower generates heat using “fan friction.” This heat source is by nature ignition free and it can be independently modulated without affecting the circulation air flow rate. The Cyclone Series® Oven is ideal for applications involving a wide range of hazardous materials, including flammable solvents and dusts that may be encountered in drying, curing and finishing applications. It is also designed with the capability to be used with programmable ramp and soak controllers.

U.S. Patent No: 11,543,136

Installation Options

- New equipment

- Field retrofits possible, contract the factory for more information

- Available within other TPS brands, contact the factory for more information

The Gruenberg Cyclone Series® is an industrial safety oven that utilizes a pair of non-sparking blowers to provide a patented ignition-free heating method. One blower circulates the airflow in the oven while a second blower generates heat using “fan friction.” This heat source is by nature ignition free and it can be independently modulated without affecting the circulation air flow rate. The Cyclone Series® Oven is ideal for applications involving a wide range of hazardous materials, including flammable solvents and dusts that may be encountered in drying, curing and finishing applications. It is also designed with the capability to be used with programmable ramp and soak controllers.

U.S. Patent No: 11,543,136

Installation Options

- New equipment

- Field retrofits possible, contract the factory for more information

- Available within other TPS brands, contact the factory for more information

- Independent blower creates heat using “fan friction” - no interior oven surface is hotter than the process air.

- Specifically engineered for safe solvent processing and is ideal for Class 1 hazardous materials, including a wide range of flammable organic and inorganic solvents encountered in drying, curing, bonding, encapsulating and finishing applications.

- Durable and cost-effective industrial safety oven design.

- Modulated rotational speed for heating blower adjusts heat input without affecting the air circulation rate.

- Unlike Class A ovens, the maximum quantity of solvent per batch is not limited.

Common Applications

- Pre-heating

- Wet paint curing

- Powder curing

- Adhesive curing

- Ink curing

- Bonding

- Drying

- Heat treating

- Pre-heating

- Wet paint curing

- Powder curing

- Adhesive curing

- Ink curing

- Bonding

- Drying

- Heat treating

- Utilizes an ignition-free heat source, mitigating the risk of atmospheric explosions and ignitions when processing Class 1, Group C & D, and Class II, Group E, F & G materials.

- The Cyclone Series® heating system is modular, making it adaptable for use on a wide range of oven styles and sizes.

- Designed for flexibility and compatible with ramp and soak controllers, enabling the generation of complex and precise temperature profiles.